November 2015

What causes Liner Curl?

16/11/15 09:47 Filed in: Technical Problems

Would you like paper or plastic? In the sign, screen and digital markets, vinyl film manufacturers generally pick paper release liners. Plastic liners are more frequently used for label stock. Paper affords many advantages compared to plastic. It is very heat stable…more stable at high temperatures because plastic can deform. Paper also provides consistent performance. Most importantly, paper is cost effective.

The disadvantage is that because it is paper, it can easily gain or lose moisture depending on the shop environment. When I worked for screen printers, it was a common practice to condition the stock the day before a print run to stabilize the sheet, so it would lay flat on the bed of the press. Sheeted material was racked face to face so the release liner could gain or lose moisture depending on the shop environment.

Changes in humidity can cause paper liners to grow or contract. When exposed to excessive humidity, some liners can grow and curl toward the print. When the liner loses moisture, it can contract causing the sheet to curl toward the liner side. See photograph A.

Photograph A

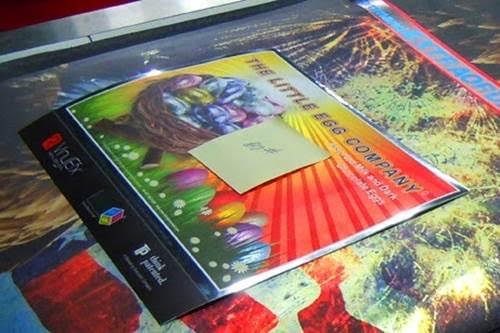

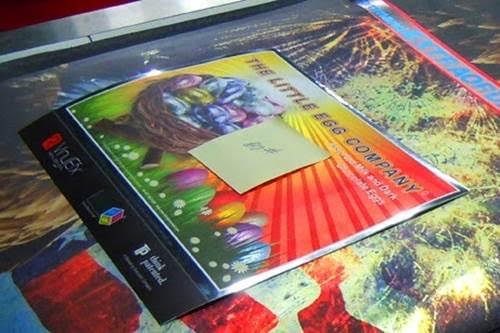

Regardless of which way the liner curls, it can give printers fits. The solution is a polycoated release liner. Typically a plastic resin is extruded onto either one or both sides of a paper sheet. This gives you the best of both worlds. You can the advantages of a plastic liner, as well as a cost-competitive paper liner. The polyolefin coating improves the resistance of the liner to moisture absorption as well as improving the overall dimensional stability and layflatness of the sheet, as shown in photograph B.

Photograph B.

Other factors, however, can affect the dimensional stability of the liner during processing at the film manufacturer or when digitally printing and laminating. Here are a couple of examples:

• During adhesive coating, the release liner is exposed to heat, which can dry the liner out. Exposed to a humid shop environment, dry liners can grow and curl. To combat this problem, many manufacturers will remoisturize their liners.

• Exposure to heat can result in the liner losing moisture, which can result in the liner shrinking causing poor layflat or sheet curl.

• Mechanical tension during lamination can stretch the overlaminate. Stretched films tend to stretch back to their original shape, which can result in the laminated print curling.

Printing with heavy concentrations of solvent or ecosolvent ink can result in the print curling. Solvent inks can consist of 70% or more of solvent. When the solvent evaporates, the inks contracts. This often results in the graphic curling to the print side as shown in photograph C.

Photograph C.

© 2014 Jim Hingst

RTape is a division of Nekoosa Holdings, Inc.

The disadvantage is that because it is paper, it can easily gain or lose moisture depending on the shop environment. When I worked for screen printers, it was a common practice to condition the stock the day before a print run to stabilize the sheet, so it would lay flat on the bed of the press. Sheeted material was racked face to face so the release liner could gain or lose moisture depending on the shop environment.

Changes in humidity can cause paper liners to grow or contract. When exposed to excessive humidity, some liners can grow and curl toward the print. When the liner loses moisture, it can contract causing the sheet to curl toward the liner side. See photograph A.

Photograph A

Regardless of which way the liner curls, it can give printers fits. The solution is a polycoated release liner. Typically a plastic resin is extruded onto either one or both sides of a paper sheet. This gives you the best of both worlds. You can the advantages of a plastic liner, as well as a cost-competitive paper liner. The polyolefin coating improves the resistance of the liner to moisture absorption as well as improving the overall dimensional stability and layflatness of the sheet, as shown in photograph B.

Photograph B.

Other factors, however, can affect the dimensional stability of the liner during processing at the film manufacturer or when digitally printing and laminating. Here are a couple of examples:

• During adhesive coating, the release liner is exposed to heat, which can dry the liner out. Exposed to a humid shop environment, dry liners can grow and curl. To combat this problem, many manufacturers will remoisturize their liners.

• Exposure to heat can result in the liner losing moisture, which can result in the liner shrinking causing poor layflat or sheet curl.

• Mechanical tension during lamination can stretch the overlaminate. Stretched films tend to stretch back to their original shape, which can result in the laminated print curling.

Printing with heavy concentrations of solvent or ecosolvent ink can result in the print curling. Solvent inks can consist of 70% or more of solvent. When the solvent evaporates, the inks contracts. This often results in the graphic curling to the print side as shown in photograph C.

Photograph C.

© 2014 Jim Hingst

RTape is a division of Nekoosa Holdings, Inc.

What ink density should I print my Silver ink at?

16/11/15 09:44 Filed in: Ink

The Color-Logic BEST Offset silver ink should be printed at a density of approximately 0.30-0.35 Status T (0.60-0.70 polarised using the black filter). Most typical silver inks would be printed at around 1.0-1.1 in density, which means that a typical can of Color-Logic silver ink would yield twice the coverage per can compared to a regular silver ink. This is why the Color-Logic silver ink is approximately twice the price of a standard silver ink.

How do the specular characteristics show up underneath laminates and or coatings?

16/11/15 09:43 Filed in: Coatings | Lamination

Most standard silver inks, such as Pantone 877, inherently dull down after applying a coating or lamination – However, our BEST Offset Silver ink (only available for conventional litho offset) has been engineered to retain its lustre when coated with water based coatings, UV coating/varnish or gloss lamination. Matt lamination will optically decrease the metallic effect due to the defused properties of the laminate. The Color-Logic BEST Offset Silver is a cleaner silver that traditional metallic silver inks, which is ideal for overprinting with process inks. For more information on our BEST Offset Silver ink click here

Do you license and support Color-Logic in foreign countries and if so, which ones?

YES. Most of our licensees are listed on our “Find a Printer” geo map. However, some businesses wish to remain unlisted.

Is there a qualification process or other requirements for Color-Logic?

16/11/15 09:41 Filed in: Test Forms | Certification

YES. Printers need to print our Print Certification Test Forms to become certified. We take color measurements across the print run to check for consistency and ensure that you’re printing to the optimum effect, based on your press, ink and substrates. Analysis is usually performed within 24 to 48 hours of receiving your submitted sheets.

It is important that when you have printed these test forms, that you send samples to Color-Logic for your report and certification. You will find two addresses at the bottom of the test forms (where you fill out your printing information), one in the US and one in the UK.

It is important that when you have printed these test forms, that you send samples to Color-Logic for your report and certification. You will find two addresses at the bottom of the test forms (where you fill out your printing information), one in the US and one in the UK.

What is the lead time for implementing Color-Logic?

16/11/15 09:39 Filed in: Installers

We ship box packaged products within 24 hours after payment. However, we also provide access to digital downloads via the Client Login section (The Vault) on our website, for instant access.

How to output files for printing with white ink

For the latest updated information regarding outputting your Color-Logic files for printing on devices with white ink and metallic substrates, please visit our Certified Presses page and our Certified RIPs page, which contains the relevant information for each printer and RIP.

Note: If the information you require is not available on our website, please contact us for more information.

Note: If the information you require is not available on our website, please contact us for more information.

Why can’t I just use a normal metallic silver ink?

13/11/15 14:14 Filed in: Ink

The Color-Logic metallic ink has been especially formulated to print underneath CMYK process inks. This metallic ink is developed to give the highest performance ensuring that the process inks trap on top. Our metallic ink is produced to a strict formula that gives the best possible luster (metallic shine) at a very thin ink film thickness versus standard metallic inks.

TOP TIP: You can replace your other branded metallic silvers inks on any job with the Color-Logic BEST offset silver and get great results. This means that if you have a job using another branded metallic silver as well as Color-Logic metallic colors, you do not need to use two different metallic inks – just the Color-Logic metallic silver! Therefore you can reduced your ink inventory by switching to just the Color-Logic range of silvers.

Metallic Silver Starter Kits

For those that are unsure as to whether their existing workflow and press configuration will work with the Color-Logic Process Metallic Color System™, Printers can purchase our Starter Kit, comprised of a CD containing pre-designed print certification artworks, Color-Logic metallic Silver inks (only for the offset, no inks supplied with flexo, inkjet or digital), and a pre-printed target chart for reference/guidance. Simply output, print and submit to Color-Logic for approval.

TOP TIP: You can replace your other branded metallic silvers inks on any job with the Color-Logic BEST offset silver and get great results. This means that if you have a job using another branded metallic silver as well as Color-Logic metallic colors, you do not need to use two different metallic inks – just the Color-Logic metallic silver! Therefore you can reduced your ink inventory by switching to just the Color-Logic range of silvers.

Metallic Silver Starter Kits

For those that are unsure as to whether their existing workflow and press configuration will work with the Color-Logic Process Metallic Color System™, Printers can purchase our Starter Kit, comprised of a CD containing pre-designed print certification artworks, Color-Logic metallic Silver inks (only for the offset, no inks supplied with flexo, inkjet or digital), and a pre-printed target chart for reference/guidance. Simply output, print and submit to Color-Logic for approval.

Why is my metallic color different to the original process color?

13/11/15 14:13 Filed in: Issues

Because you are adding a silver/grey color underneath it which is equivalent to about 20-30% black. This means that all metallic colors are slightly dirtier than the original CMYK color. The color hue will also change due to the interaction of how inks will trap (stick) on top of the metallic. This is why it is always important to use your Color-Logic color guide for selecting colors when you design your job.

TIP: The more colors and the greater the ink percentage printed over the metallic, the less the metallic will be able to show through. Think of each ink as a layer of fine silk cloth. One layer of silk can be seen through, but the more layers you stack up, the more opaque they become. This is the same with inks. All Color-Logic metallic colors take this into account.

TIP: The more colors and the greater the ink percentage printed over the metallic, the less the metallic will be able to show through. Think of each ink as a layer of fine silk cloth. One layer of silk can be seen through, but the more layers you stack up, the more opaque they become. This is the same with inks. All Color-Logic metallic colors take this into account.

What is the "BEST Offset silver ink" that you sell?

13/11/15 14:11 Filed in: Ink

Color-Logic calls it's conventional litho offset ink the “BEST” ink as it uses a special ink formulation, which is designed so that you can use a varnish, coating, sealer or lamination over your print and it won’t effect the metallic luster. Our inks have been formulated to run at a low ink density versus traditional metallic inks.

Color-Logic BEST Offset Silver part number # CL4713-BOS-01

The BEST ink name comes from the following points about the inks ability:

• Brings value to print by adding uniqueness and differentiation for your designs and customers

• Economical - combined with process inks you can produce hundreds of metallic colors

• Special effects – create effects in the image area of products by printing a combination of CMYK inks on top

• Tack – you can print process inks on top of the BEST Silver or even coat it and you will not lose the metallic effect

NOTE: All Color-Logic metallic silver inks contain aluminum pigment (flakes). They DO NOT contain any heavy alloys, which means that our ink can be recycled.

Read the article about our BEST offset ink, here.

Color-Logic BEST Offset Silver part number # CL4713-BOS-01

The BEST ink name comes from the following points about the inks ability:

• Brings value to print by adding uniqueness and differentiation for your designs and customers

• Economical - combined with process inks you can produce hundreds of metallic colors

• Special effects – create effects in the image area of products by printing a combination of CMYK inks on top

• Tack – you can print process inks on top of the BEST Silver or even coat it and you will not lose the metallic effect

NOTE: All Color-Logic metallic silver inks contain aluminum pigment (flakes). They DO NOT contain any heavy alloys, which means that our ink can be recycled.

Read the article about our BEST offset ink, here.

Why is it important to use gloss paper?

When printing a metallic ink it is extremely important to consider the base substrate that it will print onto. In most cases this would be a paper substrate. Although there are many kinds of papers in the market, it is important to consider the type of media - such as gloss, silk, matt, uncoated etc. As with all metallic ink systems, the Color-Logic system is best suited to a gloss white art paper. This type of paper has a smooth surface and will give the best holdout and reflection for the metallic inks. If you use a dull or silk paper, the metallic ink is absorbed slightly into the paper and you lose some of the metallic brilliance. If you were to use an uncoated paper, the results would decrease further. Visit our web site for a listing of certified substrates we have tested with our system.

NOTE: The surface texture of papers will also effect the orientation of the metallic pigment - this is the way in which the metallic particles reflect light. If there are microscopic pits and ripples in the paper it will cause the metallic flakes to reflect light poorly.

TOP TIP: A primer can be used to seal an uncoated paper substrate in order to create a smooth printing surface for the metallic, or a spot white ink to seal specific key areas to the print (i.e the metallic areas) can also be used.

Color-Logic certified Paper Manufacturers:

For a comprehensive list of Color-Logic certified paper suppliers, please click here

NOTE: The surface texture of papers will also effect the orientation of the metallic pigment - this is the way in which the metallic particles reflect light. If there are microscopic pits and ripples in the paper it will cause the metallic flakes to reflect light poorly.

TOP TIP: A primer can be used to seal an uncoated paper substrate in order to create a smooth printing surface for the metallic, or a spot white ink to seal specific key areas to the print (i.e the metallic areas) can also be used.

Color-Logic certified Paper Manufacturers:

For a comprehensive list of Color-Logic certified paper suppliers, please click here

What advantages does Color-Logic have over spot metallics?

13/11/15 13:58 Filed in: Spot Metallics

The Process Metallic Color System™ has many advantages over using spot metallics. As an example, if you were to produce a poster for the Olympics that had an image of the three winners and you wanted to print each of the medals that was around their necks as metallic (Gold, Silver, Bronze), using conventional spot metallic colors, you would need to print CMYK for the people, and a gold, silver and bronze color for each metallic medal... Using the Color-Logic system it is possible to produce all these metallic colors just using one metallic silver ink and overprinting with CMYK colors chosen from the Color-Logic metallic color palette!

Results:

• Traditional Spot metallic = 7 printing plates (CMYK, silver, bronze, gold)

• Color-Logic printing = 5 printing plates (CMYK + silver)

Other benefits of Color-Logic system include faster drying times, reduced scuffing and lower ink film weights meaning less ink used on press, reducing your overall carbon footprint!

NOTE: The Color-Logic system works by printing CMYK inks over a metallic base ink - if you accurately control the color density, it is very easy to reproduce a job time and time again - this is because the printer measures the CMYK patches on press and prints to their printing conditions (density, tonal value/dot gain etc) in addition to controlling the densities of the Color-Logic silver inks. Reprints of the job would always match provided the printer has good process control in place and can print consistently to their same target printing conditions with the same ink and paper. With spot metallic inks, the printer needs to mix the ink to a recipe, taking multiple colors and mixing them with a metallic ink. This is not a guaranteed process and results differ depending on how the inks are mixed. If these spot colors are mixed and left for a while before printing, the pigment can also settle in the ink and this causes the shade of that ink to change. Printers will be familiar with how difficult it is to match spot metallics colors to an existing printed job.

Results:

• Traditional Spot metallic = 7 printing plates (CMYK, silver, bronze, gold)

• Color-Logic printing = 5 printing plates (CMYK + silver)

Other benefits of Color-Logic system include faster drying times, reduced scuffing and lower ink film weights meaning less ink used on press, reducing your overall carbon footprint!

NOTE: The Color-Logic system works by printing CMYK inks over a metallic base ink - if you accurately control the color density, it is very easy to reproduce a job time and time again - this is because the printer measures the CMYK patches on press and prints to their printing conditions (density, tonal value/dot gain etc) in addition to controlling the densities of the Color-Logic silver inks. Reprints of the job would always match provided the printer has good process control in place and can print consistently to their same target printing conditions with the same ink and paper. With spot metallic inks, the printer needs to mix the ink to a recipe, taking multiple colors and mixing them with a metallic ink. This is not a guaranteed process and results differ depending on how the inks are mixed. If these spot colors are mixed and left for a while before printing, the pigment can also settle in the ink and this causes the shade of that ink to change. Printers will be familiar with how difficult it is to match spot metallics colors to an existing printed job.

Why do I have to be licensed to use Color-Logic?

13/11/15 13:57 Filed in: License

The Color-Logic System™ is licensed to printers in order to control the print production and reproducibility of our metallic system. All printers are required to demonstrate their ability to print to the Color-Logic standard. To do this each printer prints a certification form and submits this to Color-Logic for approval. The printer is then accredited and registered as an approved supplier. All designers are required by the terms and conditions of the Color-Logic system to supply work only to approved printers.

Is Color-Logic compatible with all my design software?

13/11/15 13:55 Filed in: Design Suite

In order to make designing with Color-Logic as easy as possible, Color Logic supplies pre-made color palettes and plugins for most mainstream application programs (Photoshop®, Illustrator®, Indesign®). Each palette is created using intuitive palette technology to simplify the design process so that the designer can simply “Design, Click & Color”

How can I proof my metallic designs?

13/11/15 13:45 Filed in: Proofing

There are a range of proofing systems in the market that are capable of producing Effect Proofs™. For a list of tested systems, please click here

Will Color-Logic be compatible with my RIP and workflow?

13/11/15 13:43 Filed in: RIPs

The Color-Logic System™ has been tested and is compatible with most industry standard RIPs and workflows. When outputting a Color-Logic file, the user outputs in their normal workflow for five color/spot color work. The first time you run a Color-Logic job, you may need to set up the Color Logic silver name on your RIP, this is because the Color Logic Silver separation will not be known to your RIPs lookup table of colors. Adding a spot color to your RIP is an easy process, however please refer to your Administrator or Pre-Press specialist for further assistance.

For a list of compatible RIPs and technical papers, please click here.

For a list of compatible RIPs and technical papers, please click here.

How does Color-Logic compare to MetalFX?

13/11/15 13:35 Filed in: MetalFX

MetalFX® was a metallic color system for offset printing only. It used one swatch book, printed on an offset press, and could not be adapted to flexo, gravure, heatset, inkjet, digital, or screen printing. MetalFX is no longer available. The company is no longer in business. The website explaining the process (metal-fx.com) can no longer be accessed. Like other early metallic color systems, MetalFX produced and provided color swatch books to printers and designers for their clients to match. The MetalFX swatch books were last produced in 2008, which means that any in circulation today would be out of date due to pigment fading and ink discoloration. Moreover, the MetalFX system was licensed to the printer under terms and conditions stipulating that the printer was only to use MetalFX branded inks. These inks were last manufactured at the end of December 2009 (see eckart.net), which leaves MetalFX printers with a defunct system that is no longer supported, nor with any available consumables.

Color-Logic® is a new company developing color communication systems creating special effects for print. The first Color-Logic system launched, the Color-Logic Process Metallic Color System™, encompasses a completely new, patent pending, fully chromatic process spot color space, fully accounting for ink saturation limits, transparency, and intercoat adhesion between the process inks and the new range of Color-Logic metallic inks. This new system also brings the industry new image separation algorithms to create a much more natural and photorealistic range of metallic images. Combined with an extensive range of training and support literature, online and personal WebEx training, and Master Class Tutorial Programs, the Color-Logic Process Metallic Color System is a significant advancement in metallic ink communication. The system was developed to address developments in print technology, not only for offset printing, but to technologies such as inkjet and digital metallic printing—technologies that previously were not available. Color-Logic is also developing other decorative effects systems for the design and print industry. Announcements will be forthcoming.

Printing process inks over metallics is nothing new. In fact, printers have been doing so since the late 1980s. However, unlike previous systems such as MetalFX, the Color-Logic system enables printers to produce their own metallic color charts, for their clients, based on their printing standard, or any ISO standard, or using various specifications such as GRACoL, G7, or SWOP. Since the printer produces the color charts, the printer controls the system—providing a revolutionary approach to the reproduction of special effect colors systems, including, but not limited, to metallic inks. The Color-Logic system takes into account several key variables which MetalFX and other systems did not address. These variables include allowing printers to choose and employ their own paper/substrate, printing characterization curves, process inks, ICC profiles, etc. So, unlike a generic standard swatch book printed on unknown machines, under unknown conditions, and with just one ink set and paper, printers can now tailor their own metallic charts, fingerprinted to their own equipment, and provide their clients with reproducible effects based on their own machines.

For specific product and process details please visit www.color-logic.com/how.

Color-Logic® is a new company developing color communication systems creating special effects for print. The first Color-Logic system launched, the Color-Logic Process Metallic Color System™, encompasses a completely new, patent pending, fully chromatic process spot color space, fully accounting for ink saturation limits, transparency, and intercoat adhesion between the process inks and the new range of Color-Logic metallic inks. This new system also brings the industry new image separation algorithms to create a much more natural and photorealistic range of metallic images. Combined with an extensive range of training and support literature, online and personal WebEx training, and Master Class Tutorial Programs, the Color-Logic Process Metallic Color System is a significant advancement in metallic ink communication. The system was developed to address developments in print technology, not only for offset printing, but to technologies such as inkjet and digital metallic printing—technologies that previously were not available. Color-Logic is also developing other decorative effects systems for the design and print industry. Announcements will be forthcoming.

Printing process inks over metallics is nothing new. In fact, printers have been doing so since the late 1980s. However, unlike previous systems such as MetalFX, the Color-Logic system enables printers to produce their own metallic color charts, for their clients, based on their printing standard, or any ISO standard, or using various specifications such as GRACoL, G7, or SWOP. Since the printer produces the color charts, the printer controls the system—providing a revolutionary approach to the reproduction of special effect colors systems, including, but not limited, to metallic inks. The Color-Logic system takes into account several key variables which MetalFX and other systems did not address. These variables include allowing printers to choose and employ their own paper/substrate, printing characterization curves, process inks, ICC profiles, etc. So, unlike a generic standard swatch book printed on unknown machines, under unknown conditions, and with just one ink set and paper, printers can now tailor their own metallic charts, fingerprinted to their own equipment, and provide their clients with reproducible effects based on their own machines.

For specific product and process details please visit www.color-logic.com/how.

FX-Viewer tells me that it is missing XQuartz

13/11/15 13:20 Filed in: FX-Viewer

If you are using a Mac with OS X 10.7 or greater, you will have to install XQuartz-2.7.4 or greater, you can find that at http://xquartz.macosforge.org/. According to the XQuartz documents, you will need to log off your computers user account and log back in after installing XQuartz

FX-Viewer - "Image Import" Could not render the PDF using Ghostscript" error. Please make sure Ghostscript is installed.

13/11/15 13:19 Filed in: FX-Viewer

We have setup GhostScript to RIP at a fixed 200 dpi. There is a texture size limit, depending on which GPU you use: typically 4K (4096x4096) (although this limit is 8K on high-end GPUs). So if PDF is larger than 4096 pixels / 200 inch in either dimension, this leads to an image that are too large for 3-D rendering.

So if this happens, you will need to create a smaller PDF in order to render it within FX-Viewer.

So if this happens, you will need to create a smaller PDF in order to render it within FX-Viewer.

The download link for Ghost Script does not work...

13/11/15 13:17 Filed in: FX-Viewer

The location of the Ghost Script installer has changed, please go to http://gs.color-logic.com to download.

How do I Create Movies of my FX-Viewer files?

13/11/15 09:11 Filed in: FX-Viewer

Creating a movie of your FX-Viewer design to show to your customer or for use as marketing tools for your sales force, blogs, website tutorials or presentations is extremely simple. Download the steps here.

How do I simulate all Color-Logic effects out of CMYK?

13/11/15 09:01 Filed in: Design Suite | Proofing

This Color-Logic video tutorial shows how separate C-L designs into layers using Illustrator and/or creating a composite CMYK design for use in CMYK print only (such as publications).

Basically the tutorial shows how to:

1. Convert a design into a CMYK representation of a 5 color metallic file. This will simulate all Color-Logic effects out of CMYK.

2. Split a design out into layers so that the silver is one layer and the CMYK on another.

View the video here: Splitting layers in Illustrator (a tutorial)

Basically the tutorial shows how to:

1. Convert a design into a CMYK representation of a 5 color metallic file. This will simulate all Color-Logic effects out of CMYK.

2. Split a design out into layers so that the silver is one layer and the CMYK on another.

View the video here: Splitting layers in Illustrator (a tutorial)

Linearization and calibration

13/11/15 08:57 Filed in: Linearization and calibration | Printing

We know that linearization and calibration are important when printing metallics, but how does Color-Logic measure silver and white ink to determine tone curves? Read More…

FX-Viewer System Requirements

13/11/15 08:57 Filed in: FX-Viewer

FX-Viewer Mac OS Compatibility: Mac OS X 10.5 or higher.

- Operating System: Mac OS X 10.5 - upwards

- GPU: ATI X1600 or newer, or NVIDIA GeForce 6 or newer

- Intel CPUs only

Any machine originally shipping with 10.5 or higher will be capable of running the application. Upgraded machine will require a GPU roughly 6 years old or newer. Machine without a GPU, that is, "integrated graphics" ("Intel graphics"), as found in older MacBooks, are not supported. Newer integrated graphics machines will actually run the software, but with very slow performance. For MacBooks, this means the Model Identifier at a minimum is, MacBook4,1.

In addition GhostScript must be installed in order for FX-Viewer to function, you can download it at http://gs.color-logic.com

- Operating System: Mac OS X 10.5 - upwards

- GPU: ATI X1600 or newer, or NVIDIA GeForce 6 or newer

- Intel CPUs only

Any machine originally shipping with 10.5 or higher will be capable of running the application. Upgraded machine will require a GPU roughly 6 years old or newer. Machine without a GPU, that is, "integrated graphics" ("Intel graphics"), as found in older MacBooks, are not supported. Newer integrated graphics machines will actually run the software, but with very slow performance. For MacBooks, this means the Model Identifier at a minimum is, MacBook4,1.

In addition GhostScript must be installed in order for FX-Viewer to function, you can download it at http://gs.color-logic.com

Design Suite System Requirements

13/11/15 08:53 Filed in: Design Suite | System Requirements

Minimum System Requirements

The Color-Logic Design Suite (palettes and plugins): Compatible with Adobe Indesign, Illustrator, and Photoshop CC or higher, on both Mac and Windows platforms.

FX-Viewer application is Mac only (Mac OS X 10.5 or higher)

Product support for CS6 has officially ended. We advise customers to update to the most current Adobe Creative Cloud to ensure future compatibility with Color-Logic products.

The Color-Logic Design Suite (palettes and plugins): Compatible with Adobe Indesign, Illustrator, and Photoshop CC or higher, on both Mac and Windows platforms.

FX-Viewer application is Mac only (Mac OS X 10.5 or higher)

Product support for CS6 has officially ended. We advise customers to update to the most current Adobe Creative Cloud to ensure future compatibility with Color-Logic products.

"Sizing" SBS Board for metallic ink printing

CUSTOMER SCENARIO

"We have been trialling several orders on our SBS board substrate but still not seeing the metalized reflectance that we would like. I was thinking of running a transparent white underneath the silver and CMYK to “size” the sheet to get more reflectance using conventional inks. Have you seen this applied and if so do you think it would benefit as we run on board?" Read More…

"We have been trialling several orders on our SBS board substrate but still not seeing the metalized reflectance that we would like. I was thinking of running a transparent white underneath the silver and CMYK to “size” the sheet to get more reflectance using conventional inks. Have you seen this applied and if so do you think it would benefit as we run on board?" Read More…